New Products

PLCs

Window CE PLCs

PLC Trainers

Serial Modules

Operator Panels

Control and Monitoring thru Excel

SCADAs

Voice ModulePower Supplies

Relays

Position Transducers

RS232/Ethernet Converter

Wireless Modem

Power monitoring

Protection Devices

MarqueesVariable Frequency Drives

Industrial Computer

Encoders

Application Proyects

Combos

Tech Support

DownloadsWho are we?

Our customers

How to order

Home

Contact UsTechnology To Replace Fossil Fuel

- Ethanol from biomass

- Research on other celulose alternatives.

- Learn all the processes involved in these technologies.

The world is currently needing a change to improve the vital conditions. In the quest for oil’s substitutes, researchers have been exploring renewables materials like wheat, sugar cane and oil plant, but since these ones are considered food, most of the scientists agree on the fact that food security can be affected. Recently a new trend has increased biofuel from algae (See our biofuel from algae plant)

Excellent for Research and Education.

Our bioethanol production plant is the ideal match for any research on biofuel production from biodegradable material (Biomass) or cellulose in general, allowing you experimentation from different angles.

Research

This Bioethanol production plant is sable to produce small batches of ethanol from different vegetable raw material, to allow the experimentation and research on their efficiency.

Education

This production plant can be adapted according to the education curriculum train on multivariable control in technical disciplines related to mechatronic, electrical, electronic or industrial engineering.

One of the big advantages of our plant relies on the fact the several groups of students can work simultaneously on the equipment. The control is not limited to a particular brand so you can use multiple controllers or PLC manufactures. However, if you use our PTSF1616[*] you will have a versatile and economic solution to perform both: simple and advanced process control.

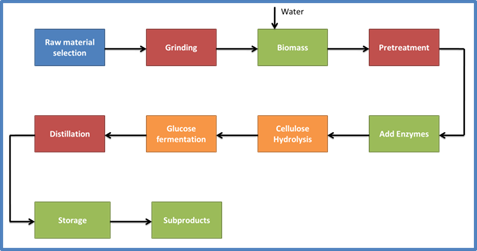

Bioethanol production process

The process of making a fuel depends on several stages, where the control of variables and raw material, are really important to obtain a very good product.

Important:In this information, because of serious patent reasons, schematics are not included. Confirming your interest all this info can be revealed to you.

Raw materials for Bioethanol production

The bioethanol can be obtained trough processing different vegetables; one of them is the cellulose coming derived from grains, sugar cane African oil palm, wood, among other. Another raw material is the starch, which can be obtained from corn, wheat, potatoes, rice, etc. For instance, the sugar obtained from the juice of sugar cane, sweet fruits, can also be used as raw material.

¿How can you order this production plant?

- Like a pilot plant.

In this version a control panel handles all the related processes and allows you for any intervention. Trough a touch panel you can perform manual or automatic operation, observing all the production variables, diagnose or stopping of the process.

This production pant is made for all of those research ad education disciplines which want to focus on the process directly and not on the control features of every device dudes. It’s guaranteed to have an easy, safe and reliable operation.

2 Like a set of control workstations.

The plant is designed no just like an integral process, but like a group of separated sub processes which can be individually operated. The variables, involved in every stage, are channeled toward an individual panel or module where can be connected to our control system PTSF1616[*] or to any other brand controller.

On every workstation, a group of students can develop all kind of control algorithm trough manual, remote or automatic control. Stand-alone or pc control also can be achieved.

This is one of the best educational tools for courses on: control, automation, mechatronics, industrial and electronics.

One of the big advantages is that every workstation doesn’t affect the others. This is very useful to simultaneously serve a bigger numbers of students. At the end of the course, all the group can collaborate together to run a production batch.

LATIN TECH INC.

PH: 305 848 3517

8004 NW 154 ST. # 621

Miami 33016, FL, USA

Discover and new experience in education and research.

More realistic lab practices

- Other Products

- Climate change Fitotron.

- Algae Biofuel Pilot Plant.

- Bioethanol Plant.

- Inverted Pendulum.

- Speed, position and generation plant.

- PLC trainer (Generic, AB, Simens, e.t.c.).

- Solar heating system.

- Hydrogen cells trainer.

- Solar and Eolic energy trainer.

- Water supply plant.

- Motor-generator plant.

- Drives.

- SCADA.

- Other didactic process (in preparation)

- Motor-generador.

- Drives

For aditional information please CONTACT US

© LATIN TECH 2005